Slurry Injection

Slurry Injection

Milestone operates the largest network of slurry injection facilities in the U.S., utilizing a patented, advanced injection technology to permanently isolate our customers' waste underground. Deep well injection is widely regarded as one of the safest and most environmentally responsible disposal methods, securely isolating waste far below drinking water aquifers. This process prevents hydrocarbons from waste from volatilizing into the air as emissions, which would naturally occur if the waste were disposed of through traditional methods like reserve pits and landfarming. The reduction in emissions realized by using our proprietary technology significantly exceeds the emissions generated from our operational activities, providing a substantial net carbon benefit.

Our proprietary process ensures compliance with regulations, and provides customers with a robust solution to ensure long-term containment while minimizing risks to groundwater, surface water and surrounding ecosystems. Milestone enables businesses across sectors to adopt a cleaner, more responsible approach to waste management, while lowering operational carbon footprints.

At our slurry injection facilities, we have the expertise and capabilities to process and dispose of a broad range of waste types, including RCRA-exempt energy waste, and both hazardous and non-hazardous industrial waste streams. Each facility is designed to handle specific waste streams while maintaining rigorous safety and environmental standards.

Learn more about Managing Energy Waste with Slurry Injection

Our protection goes deep

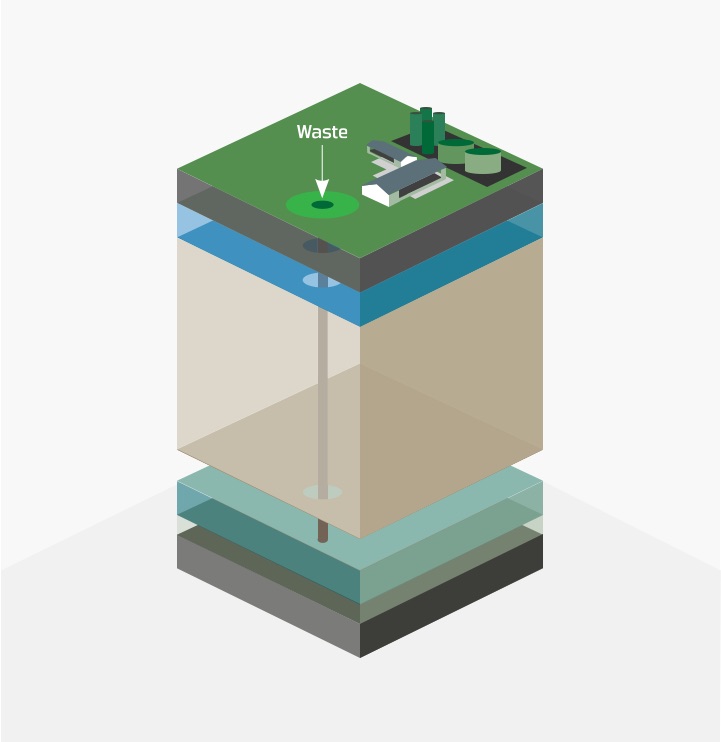

Our patented, best-in-class slurry injection process is the most cost-efficient and environmentally secure way to permanently isolate waste. We accept all RCRA-exempt, non-hazardous liquid and slurry waste streams, which are injected into carefully selected geological strata, thousands of feet below the Earth's surface. These permeable strata are capped by massive impermeable layers of rock and shale, blocking any possible migration up into our vital water resources.

For example, E&P companies pump drilling mud down the drill string to lubricate the bit during downhole rotation. Drilling mud is comprised of an oil or water base, emulsifiers, brine, dispersants, and/or gels. As the bit rotates, circulation and pressure of the fluid system moves rock fragments up the wellbore to the surface, where it is processed in a nearby reserve pit (or in a series of storage and separation tanks in a “closed-loop” regulatory system). Approximately 20% of drilling mud is recycled back into the fluid system for future use. Depending on the jurisdiction, the remainder is either disposed of onsite via reserve pit or land farming, or it is transported to a permitted disposal facility.

Reliable, safe, and compliant engineering for full assurance

We design our slurry injection facilities to go above and beyond in making sure waste is safely isolated deep below the Earth’s surface. Aſter drilling the injection well, we install multiple layers of steel casing and cement them in place, creating an impermeable barrier between the wellbore and surrounding groundwater and strata. We also perform regular maintenance and testing of the facility, and monitor the surrounding groundwater, to ensure wellbore integrity remains intact.

Milestone’s state-of-the-art Class II slurry injection facilities are designed to handle waste that is primarily liquid. Our surface equipment extracts a small fraction of incidental solids from the mud and slurry volume we receive, which we send to our landfills or others nearby. Our landfills handle both incidental solid and liquid waste streams. To prevent leakage at our landfills, we utilize advanced liner technologies and monitoring systems. Liquid waste delivered to the facilities also undergoes a dehydration or bulking process before disposal.

We have focused on carbon solutions since day one

Since its inception, Milestone has helped businesses reduce their carbon impact, long before this issue gained the urgency it has today. Our locations are meticulously chosen to deliver the best customer convenience and environmental protection. Our surface handling procedures are state-of-the-art, and our wells are engineered and constructed to perform and last. Our slurry injection process has a highly efficient carbon footprint, reducing the need for customers to purchase carbon credits to offset their emissions and helping customers potentially avoid penalties because of excessive emissions. Milestone simply offers the most cost-effective, environmentally secure waste management option.

Leading Forward For Stakeholders

Whether you are an operator, a landowner, or a policymaker, Milestone knows you are a key stakeholder in our mission. See how we are leading the charge in secure environmental infrastructure, services, and carbon solutions.

Operators

Put your waste to work

See how we are helping operators reduce their carbon footprint while mitigating environmental risk.

Landowners

Protect your land and your legacy

We provide a safe and responsible alternative to reserve pits and landfarming, allowing owners to protect their land for generations to come.

Policymakers

Shape a better future

We make it easy for policymakers to pursue a forward-looking carbon agenda that benefits all while transitioning to a more sustainable future.